High Power PV Module-Embrace the Future

2022-01-19 13:38

The solar PV industry is driven by constant technological innovation. We all remember how shocked we were when LonGi Solar launched its 166mm solar module last year. Just one year on and companies now promoting 210 and 182mm module technologies are facing great challenges.

Why is the industry promoting high-power modules?

The development of the solar PV industry is a continuous process of pursuing the lowest possible LCOE and we are now on the verge of achieving grid parity.

For PV module manufacturers, the most effective way is increasing the silicon cell area to reduce unit cost during production and finally achieve cost savings.

For end users, increasing the PV power of each string will reduce the cost per watt of the mounting structure, mounting foundation, DC cable etc. Likewise, having the same capacity on the PV plant with less mounting structure and foundation can help save on land costs too.

Each Manufacturer has its Signature Model

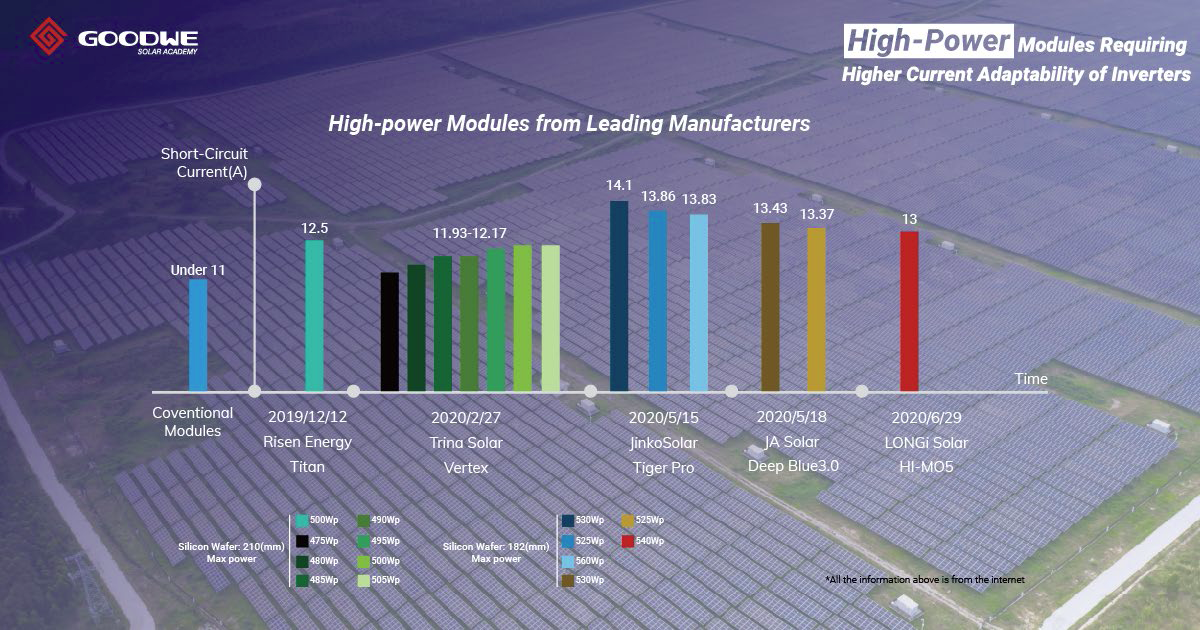

Since the launch of the 210mm wafer by Zhonghuan, the whole industry has rolled out product updates at a much faster pace. From December 2019 to June, all major players on the market have released their signature next generation products, indicating the wafer size category they belong to.

Pic1: The timeline of newly released PV module product

1) Titan - Risen Energy

On March 12, 2020, Risen Energy released its technical whitepaper to bring more confidence to the market.

This new PV module product utilizes 50 pieces of 210 large-size mono PERC wafer, each has 9 busbars printed. The wafer also applies 1/3 cut design and unique internal circuit connection methods, achieving a power in excess of 500W. The PV module efficiency reaches 20.8%. The parameters are fully adapted to the electrical requirements of the photovoltaic power station system. Compared to current 166mm(M6) wafer, the 210mm(G12) can reduce the PV module cost by 6.7%. Thus, LCOE can be reduced by 6%, and BOS costs can be reduced by 9.6% in the same project.

Malaysian solar EPC company Tokai Engineering (M) Sdn. Bhd. has placed an order for 20 MW of Titan series, which happens to be the first order for Risen for its 500 W modules.

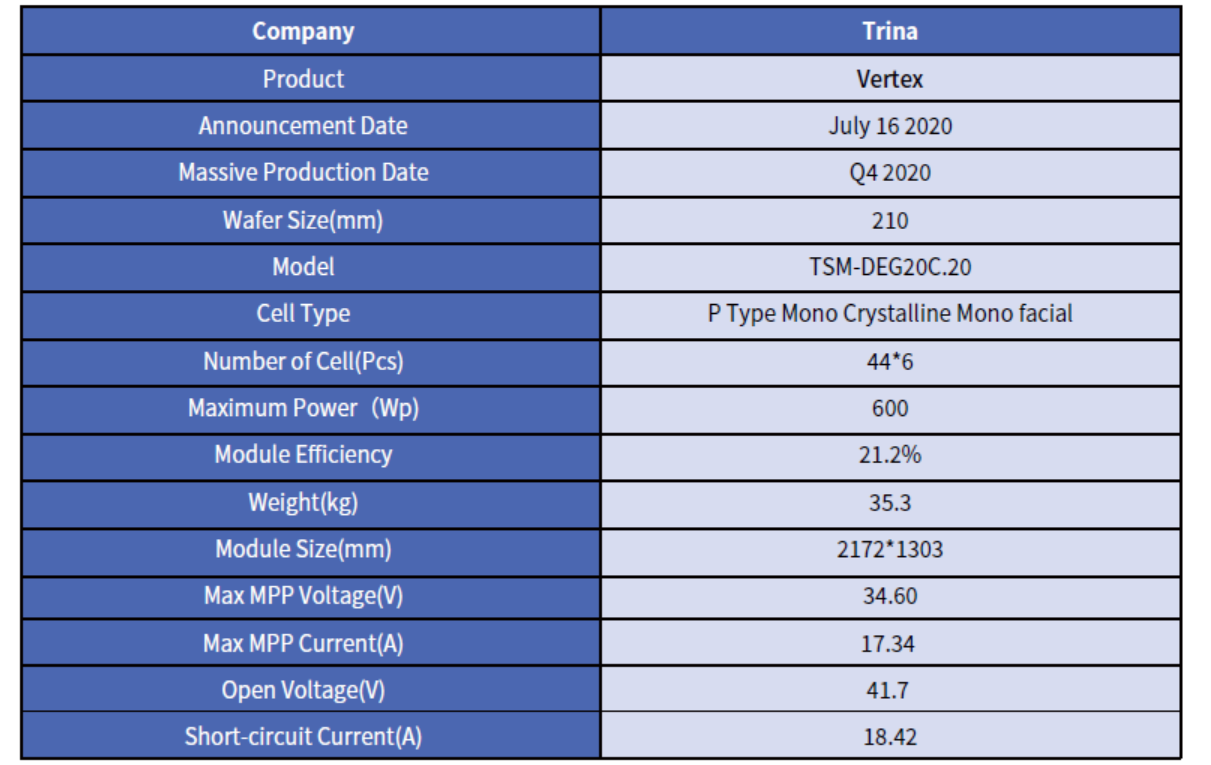

2) Vertex-Trina Solar

As the leading manufacturer of PV module, Trina made a swift response when they released their Vertex 500W+ on February 27, 2020.

500W Vertex series applies the 210mm wafer with 1/3 cut technology, the module pattern is 5*30, totally 150pcs of cells. With the non-destructive cutting technology, even 1/3 cut cell does not present any risk of cracking. The Vertex series have integrated special ribbons, shrinking the cell gap to less than 0.5mm, which increases overall efficiency by 0.2%-0.3%.

However, after less than 5 months, Trina Solar released the astonishing 600+ solar module on July 16, 2020, officially bringing the PV industry to 6.0 era. The major differences compared with the 500W+ is that the columns have been increased from 5 to 6 and the cell has been changed from 1/3 cut to half-cut, thus the pattern has been changed from 5*30 to 6*20. So, apart from the technologies like 500W+ series, the “low voltage, high current” characteristics of the 600+ Vertex series can greatly increase the string power, reducing the BOS at the DC side.

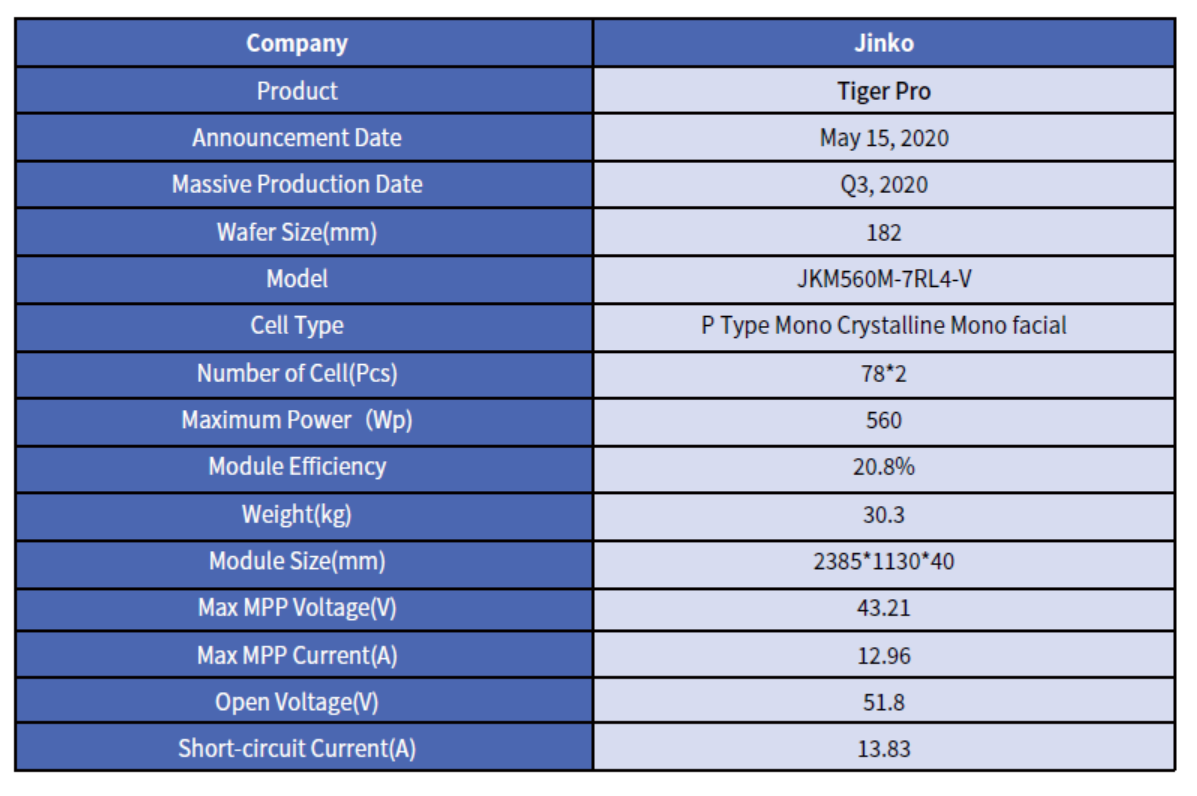

3) Tiger Pro-Jinko

Jinko is one of the most active players in the market pursuing a unique technical path. On May 15, Jinko released their 580W Tiger Pro series. The most iconic technology applied on the new product is the Tiling Ribbon(TR) technology. Instead of the traditional cell wielding, TR technology enables the edges of the cells to be stacked on top of each other, which can eliminate the cell gap to increase module efficiency significantly. What’s more, Tiger series module uses circular ribbon which is developed by Jinko R&D

independently to achieve the reutilization of light absorption and increase energy generation.

4) DeepBlue 3.0-JA Solar

JA Solar’s new generation module Deep Blue 3.0 545Wp was announced to the public on May 18, 2020. As a member of the 182mm category, the new module utilizes the newly presented 182mm cell combining the iconic Ultra-T glass. Also, the innovative 11 busbar represents the leading MBB technology in the industry. Thanks to JA Solar’s special mono PERC technology PERCIUM+ technology, the Deep Blue 3.0 545Wp can reach 23% efficiency.

5) HiMO-5 ‒ Longi Solar

On June 29th, 2020, only four days after proposing 182mm as the standard wafer size, the leading wafer and PV module manufacturer, Longi Solar, announced the new Hi-MO 5 series with a rated power of 540 W. The most impressive technology applied is the Smart Soldering technology. The integrated segmented ribbons with both triangular section and flat section can maximize light capturing and connects cells with reduced gap, reducing the tensile stress of the cell by 20%, enabling higher reliability. After acquiring gallium-doped patent from a Japanese company in March this year, Longi Solar applies Gallium-doped silicon wafers on HiMO-5, which has lower LID performance compared to boron-doped ones.

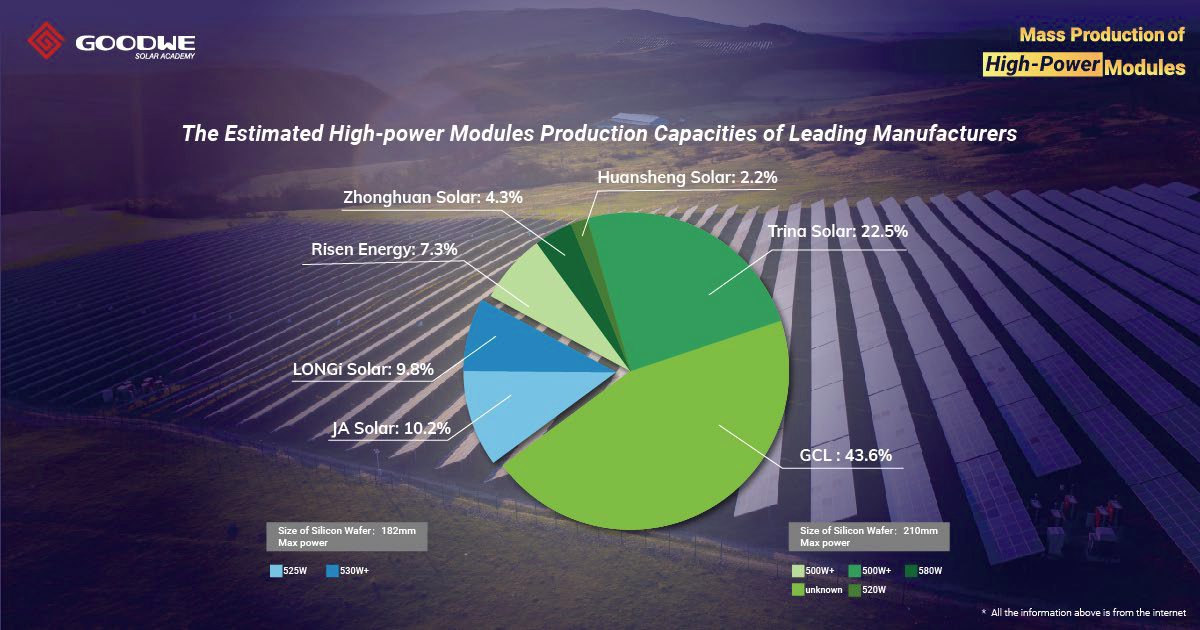

As all the main players have joined this trend, most of them have set a massive production plan with both planned and reserved capacity. According to our previous data, the 210mm category is taking the lead, but we can foresee that 182mm category will quickly catch up.

Which one is right for GoodWe inverters?

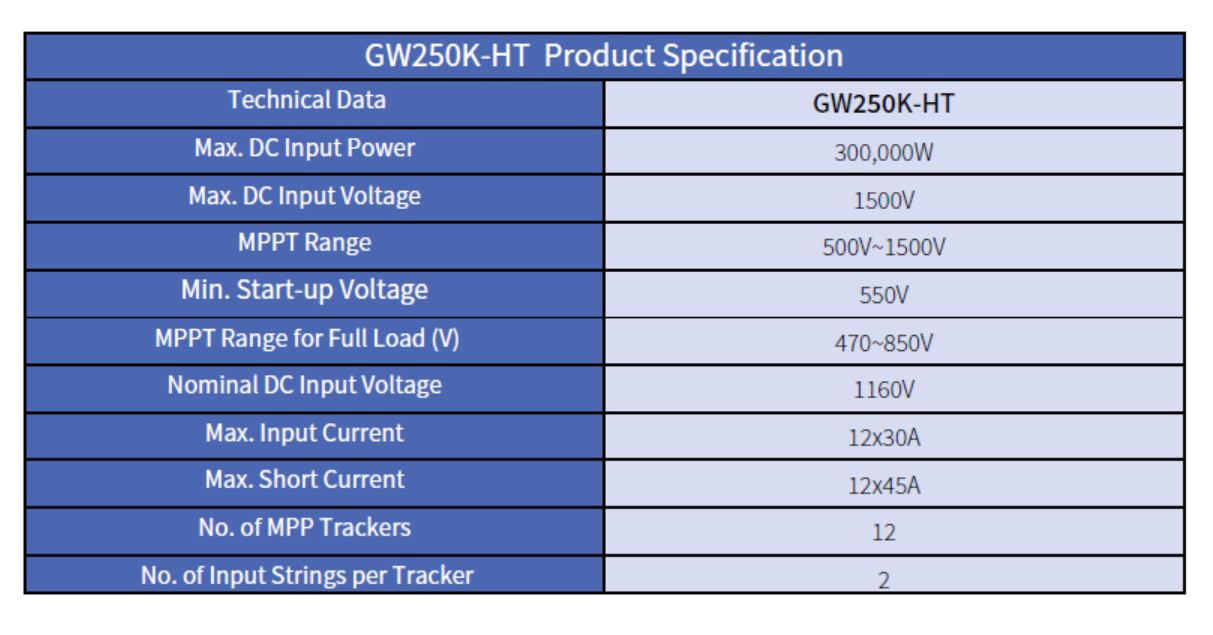

As we have introduced the technology path of the two categories above, 182mm wafer camp tends to “High Voltage, Low Current” and 210mm wafer category tends to “Low Voltage, High Current”. The system design will be totally different using GoodWe latest HT 1100V & 1500V series inverters:

1) For 182mm wafer module:

Although the modules have upgraded the wafer size from 166mm to 182mm, the key specifications for system design are within the allowance of our inverter product. Taking Jinko Tiger Pro 560W half-cut PV module as an example utilized with our GoodWe HT series:

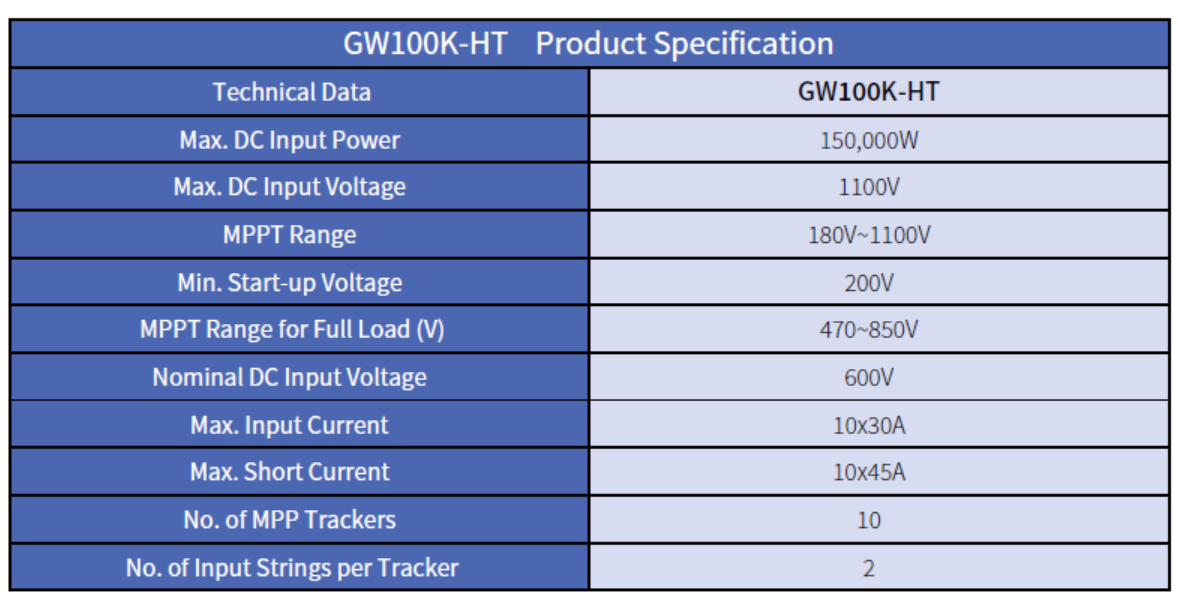

-Utilization on GoodWe 1100V GW100K-HT:

According to the calculation, without considering the temperate coefficient, each string can connect 21pcs of 560W Jinko module, and there will be totally 21pcs*2DC input per MPPT*10MPPT*560W=235,200W, thus the DC:AC ratio will reach more than 2.1, which fully utilizes the power advantages of the 182mm PV module.

During the actual application, if the DC:AC is fixed, our HT’s high DC oversizing capability can reduce the DC string connected compared with other competitors, which can save certain cover of the modules, mounting structures and DC cables etc.

-Utilization on GoodWe 1500V GW250K-HT:

According to the calculation, without considering the temperate coefficient, each string can connect 28pcs of 560W Jinko module, and there will be totally 28pcs*2DC input per MPPT*12MPPT*560W=376,320W, thus the DC:AC ratio will reach more than 1.5, which can satisfy the oversizing requirement of the most of the subarray. Also, compared with 1100V system, it can greatly reduce the BOS cost of the inverters, the PV cable consumption, the mounting structure etc.

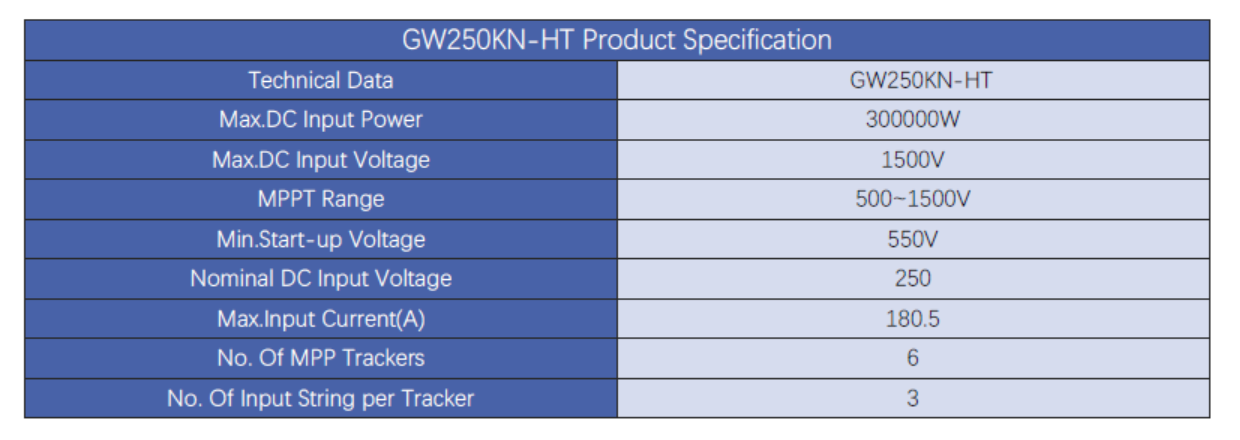

-Utilization on GoodWe 1500V GW250KN-HT:

Without considering the influence of the temperature coefficient, we can connect maximum 35pcs of Trina’s 600W module in one DC input of the MPPT, thus the total DC input power will be 35pcs*18 DCinputs*600W=378,000W, thus the DC:AC ratio can reach 1.51, which can still utilize the advantage of the 210mm high-power module during the real application.

2) For 210mm wafer module

Since most of the members from 210mm category tend to choose high DC input current as the path, almost all the string inverters cannot be used with them. However, our GoodWe HT series can handle these high-power modules with a suitable solution.

Taking Trina Solar’s latest Vertex 600W 210mm PV module as an example, the short-circuit current has reached 18.42A, which is out of the limit of most of the string inverters on the market.

-Utilization on GoodWe 1100V GW100K-HT:

Without considering the influence of the temperature coefficient, we can connect maximum 26pcs of Trina’s 600W module in one DC input of the MPPT, thus the total DC input power will be 26pcs*10DCinputs*600W=156,000W, thus the DC:AC ratio can reach 1.42, which can still utilize the advantage of the 210mm high-power module during the real application.

-Utilization on GoodWe 1500V GW250K-HT:

At present, the utilization of the 210mm wafer on our 1500V series can achieve a relatively low DC:AC ratio using the above solution based on the calculation, and we are working on the development of the new generation of inverter catering to the trend of high DC current module.

-Utilization on GoodWe 1500V GW250KN-HT:

Without considering the influence of the temperature coefficient, we can connect maximum 35pcs of Trina’s 600W module in one DC input of the MPPT, thus the total DC input power will be 35pcs*18 DCinputs*600W=378,000W, thus the DC:AC ratio can reach 1.51, which can still utilize the advantage of the 210mm high-power module during the real application.

Embrace the Future of Standardized High-power PV Modules

The market is always looking for the leading wafer size to achieve the highest returns on investment. However, the even deeper information behind the current circumstance is the PV module standardization through the whole PV industry. So, this is a tremendous advance for the whole solar industry, and everyone should embrace it.

Dear User,

Thank you for visiting our community. We would love to hear about your opinion - simply fill out and hit confirm. Thank you for your feedback!